Meat Curing Fridge Controller

I converted an old mini fridge into a meat-curing chamber. To cure meat, it's important to keep the temperature and humidity constant, often as high as 15°C. Most fridges can't do this, because their temperature controls are crude and they can't be set that warm. My solution was to create a controller that can monitor the internal temperature of the fridge, and switch the fridge's cooling compressor just by cutting power to the whole fridge.

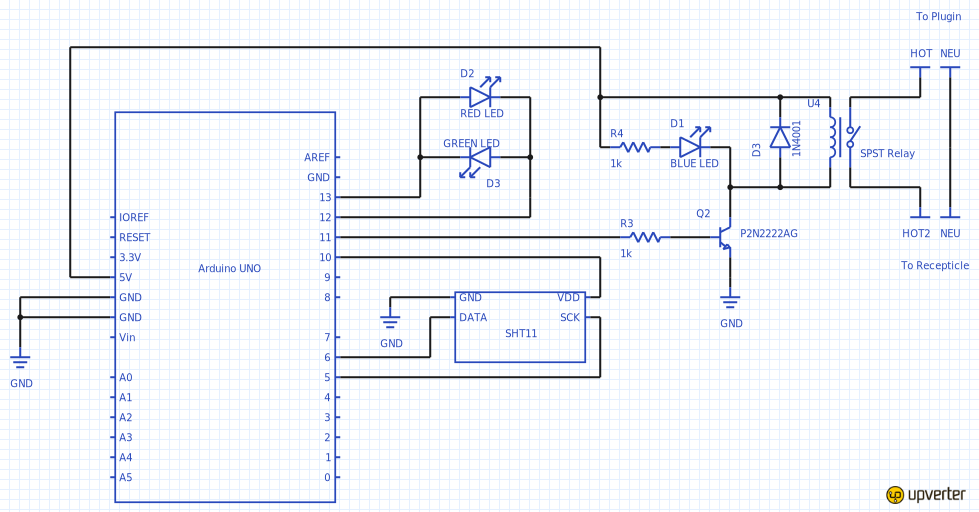

This was my first Arduino project, and really one of my first electronics projects to use a micro controller. I bought a basic Arduino Uno and a bunch of other parts from Digikey, and got to work.

Bill of Materials

- 1x Arduino Uno

- 1x Parallax 28018 (SHT11 Sensor)

- 1x 1N4001 Diode

- 1x P2N2222A NPN Transistor

- 1x PB766 Relay

- 1x Blue LED

- 1x Red/Green LED

- 2x 1kΩ Resistors

- 1x breadboard

- 1x 2-gang outdoor electrical box

- 1x receptacle

- Outdoor extension cord with male end

- Misc cat6 wire

- USB A/B cable and/or Arduino power adapter

The Sensirion SHT11 is a temperature and humidity sensor that comes pre-calibrated. You just connect it to four digital pins on the arduino and use the library. I wired mine at the end of a piece of cat6 cable that I could snake to the inside of the fridge.

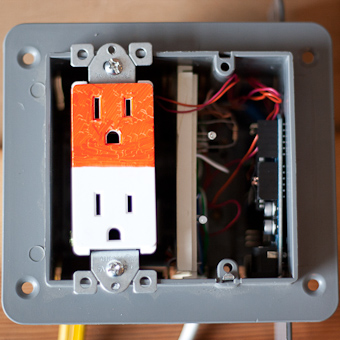

The fridge is controlled by plugging it into the orange plugin, which is switched by a PD766 relay. The white plugin is always on.

Everything is mounted in an outdoor 2-gang electrical box. I wedged a breadboard down the middle, which acts as a divider between the high-voltage side (with the receptacle and relay) and the low-voltage side (with the breadboard and arduino). A plastic window exposes the low-voltage innards so you can see the status LEDs.

Source Files

Schematic on UpverterArduino sketch on GitHub

Monitoring

Since this was my first Arduino project, and is in charge of keeping perishable food products at precise temperatures, I wanted remote monitoring to make sure it kept on working. The Arduino sketch outputs the temperature, humidity, and relay state on the serial connection, so I connected an old laptop and ran a python script to send the data to Cosm (nee Pachube).